The dimensions and arrangement of facilities in the current plant layout was used as a guide when designing the new plant layout. 61 Plant Location Buildings and Layout Before deciding plant location different factors should be analysed.

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

315 concept design of temporary market hall for atimonan fish port.

. Some processing occurs in Delaware Florida Illinois Maryland New York and Virginia. For a refrigeration plant to work efficiently it is really necessary to have a good processing plant. Since most fish processing plants are capable of processing high volumes of products foodborne outbreaks can potentially affect large sectors of the population.

PROJECT COMPONENTS Land and Building A plot of land of around 05 acre shall be required which would cost around Rs25 lakhs. The on-farm processing facility utilized a 15 feet x 15 feet area of an existing metal building. 113 Research problem In this thesis I have investigated the potential of having a fish processing plant in Kisumu.

Introduction to plant design situations difference and considerations Lesson 2. Their main products includes fresh gutted fish gutted steak fillet carcass in ice MAP or vacuum. GAA Seafood Processing Standard Page 1 Issue 4 Rev 2 Dec 2015 Global Aquaculture Alliance.

It discusses things you should think about and questions you should ask. The size of that objects oscillates oscillates between 250 500 m2. 50 Lakhs are required for the development of land depending on the topography of land.

Plant Layout 44-50 Lesson 8. For these reasons remarks and guidance on plant design are set out below Shapton and Shapton 1991 Hayes 1985 EEC. It focuses on small locally-owned fish processing operations in western Alaska but much of the handbook is relevant to any fish processing operation regardless of its location or size.

Plant Sanitation - Facility Design and Construction 23 57 Food Safety - Plant Sanitation Maintenance 24 58 Food Safety - Plant Sanitation - Cleaning and Sanitation 24 59 Food Safety - Plant Sanitation Personnel 25 510 Food Safety - Plant Sanitation Ice. Plant Layout 44-50 Lesson 8. Capacity the installed capacity of fish processing plant is 8 lakhs tin and bottles per year.

PDF PDF packaged in a food establishment or a food processing plant. The industry experienced an 18 percent increase in the quantity of fish. Most important is the plot which should be of adequate size for both present needs and future development.

The majority of these plants are in Washington Alaska Maine Louisiana and California. It is highly necessary to keep the temperature chain intact to keep the quality of the product whether it is fresh or frozen. This handbook gives advice about planning a fish processing plant in an Alaska village.

9131 Fish Processing 91311 General Fish canning and byproduct manufacturing are conducted in 136 plants in 12 states. A well designed and constructed system provides. The layout should be arranged so that raw material and finished produce are kept apart thus avoiding the possibility of cross-contamination.

Site Layout -Attach a drawing indicating. It also covers Good manufacturing practices in Food Industry Case Study for. Farm labor to process limited quantities of fish.

At seafood processing plants achieving the highest quality water standards is paramount again to prevent contamination and to attain proper moisture to keep fish products. P siinngg - BC Centre for Disease Control Design Considerations for u002639u002639Ready-to-Serveu002639u002639. Fishproplantsguidelinespdf - Read File.

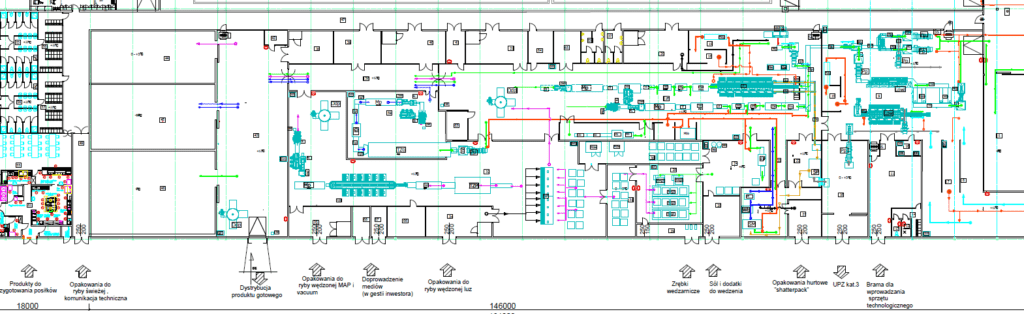

Fish processing plant design and layout pdf. The facility is designed to process. Smaller fish processing plants are in common carp or trout objects near the f ishing farms offering processed production from their own resources production.

Processing after a cleaning or washing operation should be kept apart from pre-cleaning processes. The general process flow chart of fish canning is given below. At seafood processing plants achieving the highest quality water standards is paramount again to prevent contamination and to attain proper moisture to keep fish products in the proper conditions.

2 For a refrigeration plant to work efficiently it is really necessary to have a good processing. In addition to the land an average Rs. Were expected in 1992 as well.

To demonstrate the flexibility of facility design a prototype was developed at the University of Florida. It all starts with the use of ice from the time of harvesting until it reaches to final consumer kitchen. Hazard Analysis and Critical Control Points or HACCP is a systematic preventive approach to food safety from biological chemical and physical hazards in production.

The dimensions and arrangement of facilities in the current plant layout was used as a guide when designing the new plant layout. Refrigeration is the heart of fish or shrimp processing plant. In order to make sustainable design of the fish and seafood processing equipment it is necessary to know and understand morphological properties of the fish resistance properties of the fish body formshape of the body and etc.

Layout Design Procedure 51-58 Lesson 9. We may consider any food processing operation as a transformation process. Download full-text PDF Read full-text References 10 Abstract The success of any production system relies greatly on farm design and construction.

However the extent and detail of the activities behind each stage are different with every projectThere are a number of different industry formats for mapping the stages in the engineering process. The plant should be close to public transport Access to electricity water and steam is essential. Food plant design process 21 Introduction The design process on all projects follows the same stages of development.

Process Plant Layoutpdf - Read File Online - Report Abuse. The layout should ensure that drainage is always away from the finished product and other clean areas. Applications for licensing of a fish processing plant.

Fish Processing Plants HACCP - 1 - INTRODUCTION There are a variety of potential hazards for most foods many of which can occur during the processing stage. An example floor plan is shown in Figure 1.

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

Planing Fish Processing Plant Detail Dwg File Chic Kitchen Decor Plants Fish

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

Establishments And Production Demands For Freshwater Fish Processing

Pdf Modelling And Simulation Of A Fish Processing Factory Ship Semantic Scholar

Fish Processing Plants Design Equipment Technological And Construction Projects

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

0 comments

Post a Comment